Rumba it consists of a printing bed on 3 Z screw raisers that work

indipendently not only to find the perfect bed alignment with the nozzle

each print automatically, but also to tilt the print up to 40 degrees in any direction helping thus with printing without supports if you manage to get your hands or make your own non planar slicer. This adds 2 more axis to your printer making it a 5 axis non planar capable machine

for cheap (such machines costs thousands of dollars just for the add

ons in the industryes that need them like CNC milling etc) powered by 3

closed loop stepper motors to create te Z, U and V axis.

This set of STL files is for the 200x200mm printing bed. It can tightly accomodate up to 300300 mm printing beds too.

You will need to build a frame using 8 20X20 aluminium profile lenghts cut at preciselly 420mm ech and four 20X20 aluminium lenghts cut at preciselly 390mm each.

With the long profiles you will make two frames (for top and bottom) using the other 4 lenghts as vertical frame legs. On two (paralel on top of eachoter) lenghts of 420 that are at the longer distance for the opposite ones (your top and bottom frames will be not equal squared each but rectangular) at the dead center place a sliding rod fixer on each profile perfectly alligned with eachother, place in a rod from top to bottom, take you pre cleansed and fitted togenther Rumba platform and slide in the centering rod bearing tube of the central aligner onto the rod than slide the rod down into the lower clamp and fix it for good.

Now you can place the opposite two aligning clamps on the bottom opposite profile accoridng to the Rumba platform, (leave enough room between them for the access to the motor support bolts to work with) put the Rumba other two centering rod bearing tube aligners on top of the clamps, slide in two rods, slide on them on top the counterparts clamps and lock them on the top profile.

Now you can fit the motor supports and motors, their threaded lifting Z axis studs and brass nuts, and your Rumba is ready ro the first testings once hooked into the motherboard.

From here on is ordinary administration, placing the end stop click switches (3 on the bottom level of each rod centering bearing, other 3 at the top end, one inside each alignment mechanism of the Rumba paltform underneath by the central gear to prevent the excess resulting in pulling of the alignment rods to snap them, total 9 switches)

On top we reccomend to run a Core XY or similar gantry system for the X and Y axis with a top down mini Z auxiliary axis that holds the printing head.

Rumba 5 axis platform, 200x200 printing bed size (can take also up to 300X300 mm printing bed size)

- Brand: 3D Mential

- Product Code: Rumba 5 axis platform, 200x200

- Availability: In Stock

-

£10.00

- Ex Tax: £10.00

Related Products

Tools holding jar 40mm outer diameter, 4mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for mini dremel bitsH 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bitsH 80mm mainly for long thin tools like thin screwdrivers, punchers and twizzers, also some ..

£3.00 Ex Tax: £3.00

Tools holding jar 60mm outer diameter, 6mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for mini router bitsH 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bitsH 75mm mainly for long thin tools like screwdrivers, punchers and twizzers, allen keys an..

£3.00 Ex Tax: £3.00

Tools holding jar 80mm outer diameter, 8mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for router bits, beveling tools, etc.H 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bits,handled tools like tapping handle or chuck keys.H 100mm mainly for long&n..

£3.00 Ex Tax: £3.00

Tools holding jar 120mm outer diameter, 12mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 50mm mainly for router bits, beveling tools, etc.H 75mm mainly for larger head bits and longer flute tols like tapping tools and drill bits,handled tools like tapping handle or chuck keys.H 100mm mainly for long..

£3.00 Ex Tax: £3.00

Tools holding jar 160mm outer diameter, 16mm honeycomb spacing.

H 50mm mainly short thick for router bits, beveling tools, etc.H 100mm mainly for larger head bits and longer flute tols like tapping tools and drill bits, handled tools like tapping handle or chuck keys, pliers, snip, clippers, and other wrenches.H 150mm mainly for long tools like big scr..

£3.00 Ex Tax: £3.00

Ballerina line of multiaxis 3D printers turntable, for 200X200 printing bed

Ballerina is a turntable that rotates the printing bed ad infinite left and right as needed by the printer allowing the machine to print at any angle in any given position always against gravity, hence witout supports, powered by a closed loop stepper motor. The main purpose is to make..

£10.00 Ex Tax: £10.00

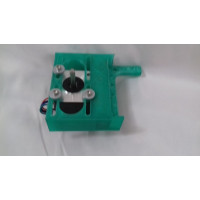

Tensioning bracket for nema 17 stepper motors STL file

This is a bracket designed so you can fit in a Nema 17 stepper motor, slide it to the nearest end to put the belt on the pulley, than hand drag it away to tension the pulley as needed before locking the bolts on the motor.On one end it has a set of holes on a lower level to fit over the cliff of a g..

£3.00 Ex Tax: £3.00

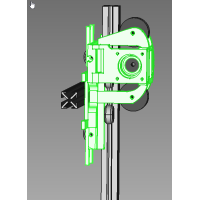

Mini Z axis; top down carrier

This project can be used for many 3D printers based on Core X,Y, systems and similar gantry systems that have the Z axis on the printing bed and the X and Y axis on a top gantry that does not perform Z axis movements.Truth is that when you want to print Non Planar sliced geometries thre is a limitat..

£5.00 Ex Tax: £5.00

Tags: Rumba 5 axis platform, 200x200, non planar printing, non planar slicing, multi axis printing, no supports, overhang, supports