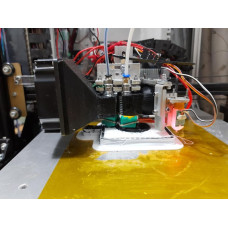

Horizontal and vertical sucking funnel for 40mm up to 80 mm fan to cool a V6 heatsink so I can print Policarbonate carbon fiber filament at 270C, if this is not good enough. The point is I am printing with a cheap Core XY or gantry printer and went to print around 300C, Polycarbonate and similar, and the Volcano 6 heatsink simply wouldn't cool enough with a 30X30 fan, so I went 50X50 with a straight funnel in PETG, and 2 things happen, one, it worked, second, it collided with the frame, the fan is too big so when I home it on Y... crash. Besides the lower part of the funnel clamp on the V6 started melting, not suitable for such temperatures.

So I went for a bent up funel to keep my 50X50 fan out of the frame,

suck in colder air (The other one was technically sucking right above

the 100C heated bed), than I went 80X80mm fan...

All attached to my manual tool swap system.

You want higher glass transistion temperatures materials, like Nylon, Policarbonate and anyway something thet can hold fast at 100C, this also means you have to print them at higher tempetaures, so modify your printer to be able to withstand 300C nozzle temperatures and higher please.

3D printing settings

I always print tools at 100% infill, 120% flow and the layer width larger than the nozzle (0.4 mm nozzle I print it at 0.5 width and 0.3 height) at the hoter end of that material, to improve adhesion, eliminate air micro gaps, make the part more resistant in use, and yes, that generates stringing, but I set my slicer to comb inside over the infill, so some of it is taken care of it this way.

Volcano 30X30 fan adapters to larger fans

- Brand: 3D Mential

- Product Code: Volcano Heatsink adapters to enhance cooling.

- Availability: In Stock

-

£5.00

- Ex Tax: £5.00

Related Products

Tools holding jar 40mm outer diameter, 4mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for mini dremel bitsH 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bitsH 80mm mainly for long thin tools like thin screwdrivers, punchers and twizzers, also some ..

£3.00 Ex Tax: £3.00

Tools holding jar 60mm outer diameter, 6mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for mini router bitsH 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bitsH 75mm mainly for long thin tools like screwdrivers, punchers and twizzers, allen keys an..

£3.00 Ex Tax: £3.00

Tools holding jar 80mm outer diameter, 8mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 25mm mainly for router bits, beveling tools, etc.H 50mm mainly for larger head bits and longer flute tols like tapping tools and drill bits,handled tools like tapping handle or chuck keys.H 100mm mainly for long&n..

£3.00 Ex Tax: £3.00

Tools holding jar 120mm outer diameter, 12mm honeycomb spacing.

We cover here three heights of the same diameter jar with the same honeycomb spacing H 50mm mainly for router bits, beveling tools, etc.H 75mm mainly for larger head bits and longer flute tols like tapping tools and drill bits,handled tools like tapping handle or chuck keys.H 100mm mainly for long..

£3.00 Ex Tax: £3.00

Tools holding jar 160mm outer diameter, 16mm honeycomb spacing.

H 50mm mainly short thick for router bits, beveling tools, etc.H 100mm mainly for larger head bits and longer flute tols like tapping tools and drill bits, handled tools like tapping handle or chuck keys, pliers, snip, clippers, and other wrenches.H 150mm mainly for long tools like big scr..

£3.00 Ex Tax: £3.00