Printer upgrade STL 3D printable files

Make your machine work better, prnt better, more quiet, print head swapapble with no effort, water cooled, get smarter cable management system, anything goes if you can actually print it yourself from a file you bought online.

3D Printer suspensions leggs on tennis balls

Noise damper too. I went to see what it would cost me to have my printer more quiet while working, all that vibration on some Aluminium legs against the desk wood surface was acting like a guitar amplification effect, and the prices made me invent someting cheaper, those cups are held with ..

£3.00 Ex Tax: £3.00

Clamp spinning handle

As from the name this is a clamping up spinning handle that can pretty much clamp against anything you need to spin like a cable reel, filament spool, etc.In the ZIP file you have one lower element, one upper element, one handle pipe and one nut knob, for which you need to buy a kerneled M5 inse..

£3.00 Ex Tax: £3.00

Filament spool support

My take on a filament spool support, accoding to how long is the Aluminium 20x20 extruded bar it can take quite a large number of filament spools from 500 grams to 1Kg to 3 Kg to 5 Kg, the rod that holds the spool is 6mm steel and on the rod there are 30mm or 50mm or 70mm drum adapters according to ..

£5.00 Ex Tax: £5.00

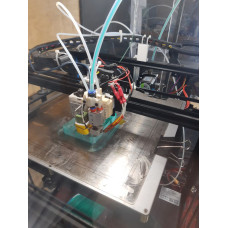

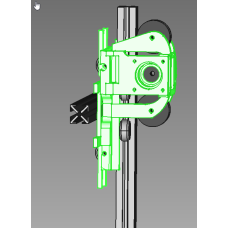

Flip Automated tool Changer

Swapping the print head is a mess, wires, screws, nuts, bolts, carriage, all taken apart, one day of work just to swap a Chimera for a Volcano, and this is before you go into the firmware settings.It doesn't have to be that way.You can have the easy life after you printed this light and compact..

£5.00 Ex Tax: £5.00

FLIP, the cheap reliable tested tools swap system by hand.

Swapping the print head is a mess, wires, screws, nuts, bolts, carriage, all taken apart, one day of work just to swap a Chimera for a Volcano, and this is before you go into the firmware settings.It doesn't have to be that way.You can have the easy life after you printed this light and compact..

£5.00 Ex Tax: £5.00

Mini Z axis; top down carrier

This project can be used for many 3D printers based on Core X,Y, systems and similar gantry systems that have the Z axis on the printing bed and the X and Y axis on a top gantry that does not perform Z axis movements.Truth is that when you want to print Non Planar sliced geometries thre is a limitat..

£5.00 Ex Tax: £5.00

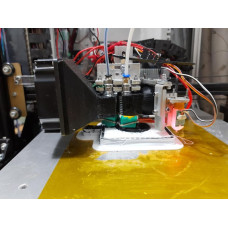

Volcano 30X30 fan adapters to larger fans

Horizontal and vertical sucking funnel for 40mm up to 80 mm fan to cool a V6 heatsink so I can print Policarbonate carbon fiber filament at 270C, if this is not good enough. The point is I am printing with a cheap Core XY or gantry printer and went to print around 300C, Polycarbonate and simil..

£5.00 Ex Tax: £5.00

Z axis rod drop down bearing supports for 8mm threaded studs

Many cheap 3 d printers have the Z axis climbing up and down on threaded rods, one end (usually the bottome one) attached to the stepper motor, the other one.... free to wobble.And this causes some issues with the printing process.Locking the other end from wobbling is something that actually improv..

£5.00 Ex Tax: £5.00