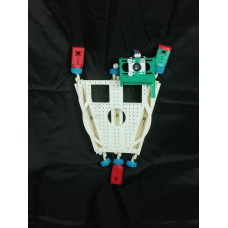

Rumba it consists of a printing bed on 3 Z screw raisers that work

indipendently not only to find the perfect bed alignment with the nozzle

each print automatically, but also to tilt the print up to 40 degrees in any direction helping thus with printing without supports if you manage to get your hands or make your own non planar slicer. This adds 2 more axis to your printer making it a 5 axis non planar capable machine

for cheap (such machines costs thousands of dollars just for the add

ons in the industryes that need them like CNC milling etc) powered by 3

closed loop stepper motors to create te Z, U and V axis.

For

the price you have one kit for the 200X200 bedsize of Rumba, as pried

off the printing bed, no supports removed, no post printing proecssing

of any kind. You wil need to use box cutter, file, dril bit and other tools to remove supports, clean the parts, sandpaper to smooth them and than fit them to check, when everything is working fine, you will have to take them apart for the last time and greas all the parts that sotate or slide than fit it back together. The order of operations is as follows:

-with all parts cleansed insert the nuts on the long bars than fit the end supports for the lead scrwes and guided sliders tight, it shouldnot allow any play, but will rotate with difficulty (before greasing) If not roatating and swinging than remove them out and checkfor the places with wear and tear from the attempt, snad them well before trying again.

-all sliders come in pair, one with a motor end cap and one with a sliding bar end cap, put them into the sliding slots accordingly;

central slot narrow side; motor,

central slot wide side guide,

extremities wide side motor,

extremities narrow side glides,

extend the central pair until it meets at the center with the end stoppers,

insert the giuding gear, insert the bolt, place the nut underneath and tighten enough to have the gear rotate without any play,

repeat for the other two equalisers.

If all works and at any pull of one slider the counterslider follows suit, than you can take them appart and grease them carefully with a sort of grease that will not melt or glue the type of polymer you choosen. You rock.

You need to buy the nuts and

bolts, closed loop steper mototrs and lead scrws with brass nuts

couplings plus the 8mm diameter guide rails and ball bearing sliders and

all the metal supports to connect them to the printer frame.

Word of advice from experience, PLA will fail in time due

to proximity of hot elements like heated bed or the hotend, but can

print in an open printer frame over 100 hours before it fails sometimes.

If

you intend to run your printer on the hot side of polymers do not go

for PLA, rather nylon, or PPS or similar, if you intend to go fully

enclosed and really hot polymers in printing, I reccomend you go PEI or

PEKK.

Rumba 5 axis platform 200X200 3D printed on demand

- Brand: Maker

- Product Code: Rumba 5 axis platform 200X200 3D printed on demand

- Availability: In Stock

-

£122.00

- Ex Tax: £100.00

Available Options

Related Products

Ballerina line of multiaxis 3D printers turntable, for 200X200 printing bed

Ballerina is a turntable that rotates the printing bed ad infinite left and right as needed by the printer allowing the machine to print at any angle in any given position always against gravity, hence witout supports, powered by a closed loop stepper motor. The main purpose is to make..

£10.00 Ex Tax: £10.00

Tensioning bracket for nema 17 stepper motors, 3D printed on demand

This is a bracket designed so you can fit in a Nema 17 stepper motor, slide it to the nearest end to put the belt on the pulley, than hand drag it away to tension the pulley as needed before locking the bolts on the motor.On one end it has a set of holes on a lower level to fit over the cliff ..

£5.00 Ex Tax: £5.00

Tags: Rumba 5 axis platform, 200x200, non planar printing, non planar slicing, multi axis printing, no supports, overhang, supports