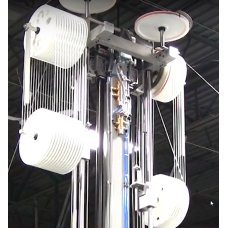

Desktop Filament Extrusion Spooling line. Recycle polymers, make your filament for free (nearly)

Level Winder spooling machine

I will latter on provide the motehrboard and algorhitm to separate teh level winder from the spooler and drive it proportionally with a pairing algorhitm.

The problem is that each new row is a tad longer due to slightly larger diameter, so let's assume first row, diameter 62mm width 30 filament strings (60mm) comes out perfect, second row is not 62 mm diameter anymore, but is on top of that, making it 65.4 mm diameter, but mechanically tied level winders with a belt from pulley to pulley like this cannot compensate for that on the flight, so second row will not be as perfect as the first row, third row even less, and you go 28 rows up.... at least untengeled.

But this can be tackeld with an arduino, two separate stepper motors talkimg to eachoter, and and algorhitm so that when the spooling motor has counted 30 rotations and it starts the second row, the level winder motor adjusts itslef to return at the end after a slighlty longer period. Industrial machines have that for 100 years, so I think it can be done.

But for now is mechanically coupled with a belt, and you don't even need motors, you can print yourself a spools clamp, clamp it on the spool, and rotate by hand to respool occasionally, it works, i tested it respooling more than 10KG.

This level winder machine if you go to buy it with all the mechanics and electrics plus electronics and codes, it goes areound 3000 USD or more, if you buy it from me as STL files, is 40 USD per version, or all versions bundeled in one (the only thing that differentiates them is the core aligner, so you buy all cores in one bundle) 50 USD plus some 4 KG of filament, say another 120USD plus some M16 X 300mm studs, 4 bearings OD 36mm, ID 16mm, width 11mm, M16 nylock nuts, washers, rubber O rings, a bunch of M3, M4 and M5, M6 bolts, nuts and threaded inserts, sealant glue (structuralsilicone) you have it all around 200 USD, plus motor and electronics, maybe 300 USD. Plus a week of printing, filing, sanding, lots of sanding, drilling, inserting threaded inserts with the soldering iron.

Nice savings.

Extrusion line filament tensioner for perfect diameter of filament.

The tensioner spool machine is a dual gear puller where one of the axis is powered and the other axis is taking the power from the dual gear system. Once printed you will need to fill the pulleys with Structural Silicone (Glue Sealant) up to the level of the geared teeth, than let it cure a ..

£5.00 Ex Tax: £5.00

Filament accumulator kit

The production of 3D printer filament is hindered by a few major limitations, one being the requirement of uninterrupted filament extrusion without any changes in temperature, speed, or pulling tensioner. To address this, an accumulation buffer mechanism is needed to store the produced filament ..

£5.00 Ex Tax: £5.00

level winder (no spooler) kit for filament 1.75 mm for 1 Kg spool

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£5.00 Ex Tax: £5.00

level winder (no spooler) kit for filament 1.75 mm for 3 Kg spool

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£5.00 Ex Tax: £5.00

level winder (no spooler) kit for filament 3 mm for 3 Kg spool

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£5.00 Ex Tax: £5.00

level winder and spooler kit for filament 1.75 mm for 3 Kg spool

If you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breaking in the Bowden tube, you ne..

£7.00 Ex Tax: £7.00

level winder and spooler kit for filament 1.75 mm for 1 Kg spool

If you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breaking in the Bowden tube, you ne..

£7.00 Ex Tax: £7.00

level winder and spooler kit for filament 3 mm for 3 Kg spool

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£7.00 Ex Tax: £7.00

level winder kit (no spooler) for filament 3 mm for 1 Kg spool

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£5.00 Ex Tax: £5.00

Level winder plus spooler for filament 3mm diameter for 1Kg spool.

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£7.00 Ex Tax: £7.00

Level winder with spooler, fiament accumulator and filament tensioner for extrusion line, complete kit

level winder and spooler kitIf you need to extrude your own filament besides the extrusion machine, you will need to wind it nice and untangled, if you have tangled filament you will need to re-spool it untangled, if you have brittle annealed filament on a regular spool and keeps breakin..

£10.00 Ex Tax: £10.00

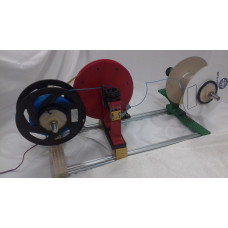

Spooler kit (no level winder included)

Spooler kit; Can spool anything that can be fitted onto the axis in betwen the centering cones, Filament, Wire, String, as long as is not hoist cables or other tough to spool things.If you want to spool pretty fast you will need a level winder.Here is how it works without a level winder, yo..

£5.00 Ex Tax: £5.00