This project can be used for many 3D printers based on Core X,Y, systems and similar gantry systems that have the Z axis on the printing bed and the X and Y axis on a top gantry that does not perform Z axis movements.

Truth is that when you want to print Non Planar sliced geometries thre is a limitation of how deep you can go following the printed profile, and this limitation is given by the Z axis movements that will collide your print to the top gantry unles... you have a Top Down Z axis that can extend to reach deep below your printers normal capabilites.

It also comes in handy when printing in more than 3 axis, like with the Rumba 5 axis printer, Tango 7 axis printer and Bollero 5 axis rotary system printer.

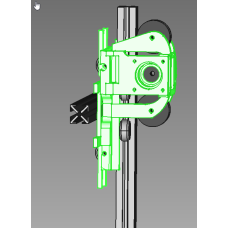

Two versions are presented here one has the motor mount as close as possible to the gantry, and is called V3 (third version) and one has the motor mount above the gantry beam 35mm, to provide clearance, and is called V2 (second version); V1 was an attempt to build everything more compact but in practical tests provided problematic to tune, center and have reliability issues. So I scrapped the version alltogheter.

You will need to also buy 10 V grove wheels for aluminium profiels, and obviously 10 off center spacers to regulate the pressure of each wheel on the Aluminium profile. Also M5 bolts X 45mmm at least two, M5 bolts 40mm long at least 4 and M5 bolts 35mm long at least 4, plus the motor mounting M3 bolts and some other M3 botls to lock the bearings and the belt tensioner in place, nuts, washers, etc. also buy online some bearings I.D. 8mm, O.D. 22mm, widht 7 mm or near by. The bearings go to support the belt pulley on the motor axis.

You will ned 2 M6 bolts long 40mm to lock in place the belt end caps on the Aluminium profile by threading into the aluminium profile core hole both ends for 40 mm deep.

Also you will need two belt idler pulleys and one belt timed pulley to complete the system.

Attention, V2 is a bit more fiddley to fit the V grove wheels onto, there is a horizontal support under the motor mount that is in the way. That horizontal printed piece is there only to aid with printing, it has no structural meaning at all, and can stay tehre for ever but... in the V2 case you will have to eliminate it on one side of the motor mount to make room to fit the Vprofile wheel. I used a hacksaw blade to cut it off.

Mini Z axis; top down carrier

- Brand: 3D Mential

- Product Code: Mini Z axis; top down carrier

- Availability: In Stock

-

£5.00

- Ex Tax: £5.00

Related Products

Rumba 5 axis platform, 200x200 printing bed size (can take also up to 300X300 mm printing bed size)

Rumba it consists of a printing bed on 3 Z screw raisers that work indipendently not only to find the perfect bed alignment with the nozzle each print automatically, but also to tilt the print up to 40 degrees in any direction helping thus with printing without supports if you manage to get your..

£10.00 Ex Tax: £10.00

Ballerina line of multiaxis 3D printers turntable, for 200X200 printing bed

Ballerina is a turntable that rotates the printing bed ad infinite left and right as needed by the printer allowing the machine to print at any angle in any given position always against gravity, hence witout supports, powered by a closed loop stepper motor. The main purpose is to make..

£10.00 Ex Tax: £10.00

Flip Automated tool Changer

Swapping the print head is a mess, wires, screws, nuts, bolts, carriage, all taken apart, one day of work just to swap a Chimera for a Volcano, and this is before you go into the firmware settings.It doesn't have to be that way.You can have the easy life after you printed this light and compact..

£5.00 Ex Tax: £5.00

Tags: Non Planar, Z axis, top gantry, Top Down Z axis,