if you have tangled filament you will need to re-spool it untangled,

if you have brittle annealed filament on a regular spool and keeps breaking in the Bowden tube, you need to soften it two hours at 50C if PLA, 70C if ABS, HTPET or PETG, 100C if Nylon etc, than in the same hot setup you need to re-spool it on a 200mm large core spool (yes, you might need to make one out of a 200MM diameter bit of PVC pile and some thin plywood for sides) than leave it re-spooled another 2 hours at same temperature, than let it cool slowly, than you can print with it alright.

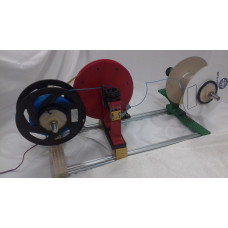

Here

is how it works without a level winder, you can produce 1 Kg in maybe 5

but mostly 7 hours. With a level winder you can extrude up to 10 -15

kg per hour. With this version maybe 5 Kg per hour.

Always print with 100%

infill,PLA is good for a machine used now and than at room

temperature, if your machine will stay or be used in hot environment

(like a shed under sun) use at least ABS or PETG (noe of them too

resistant in time, like PLA) or Nylon (PolyAmide) or PPS.

This

kit contains the following 3D printable items:

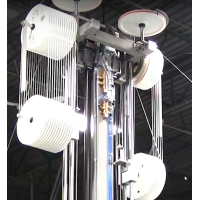

Level Winder

kit:

one twin left/right thread guide,

one path finder that will travel on that guide

one carrier for the path finder that also moves the filament left and right to avoid tangling on the spool

one stand leg (print two)

one stand base

one level winder breadboard base

one

pulley base diameter 100mm (to be fitted on the 8mm axis, it takes

all pulleys from 20mm diameter to 90 mm diameter)

Pulleys from 20 to 90mm diameter to be

fitted on the pulley base as needed

One pulley base diameter 220mm

(to be fitted on the 8 mm diameter axis, it takes the larger than 100

mm diameter pulleys)

one aligner to fit under the carrier

You

need to buy elsewhere: Inserts of metric 3 to put into the pulley

base 6 of them, one per each hole, metric 3 sunken head bolts various

lengths, stainless steel rod 8mm diameter that you need to cut at

175 mm and drill a hole diameter 3mm at 4 or 5 mm form one end

side to side to hold the bolt that locks the pulley, than when the

twin thread guide is printed, you drill through in the centre hole

with an 8mm diameter drill bit to clean the axis hole (those drill

bits are slightly less than 8mm, which is good, makes it a tight fit)

and than hammer through the axis hole the 8mm diameter rod such that

the end with the 3mm hole sticks out one side for 38/40mm.

You also need two stainless steel large washers 8mm hole and 30mm outer diameter or whatever is near buy, plus two 3mm bolts long 20mm for the aligner and 4 M4 bolts long 20 mm to bolt the legs onto the support, plus 4 M5 bolts long 25mm to fit the assembly onto the breadboard support base.

After you assembled the level winder and put the finder into the carrier, dry run test it by hand while holding the finder down with one finger so it does not pop out. If happy with the results that take a 3.5mm drill bit and drill a hole in the side of it through the carrier side opening, fit in an Allen key head bolt M3 with a nyloc nut to keep it from flying out in operations.

Spooler kit;

One stand for roller axis

one

breadboard base

various pulleys

one centring cone without pulley

one

centring cone with 20mm short pulley

one centring cone with 50mm long

pulley

Various motor supports (Nema 17, Nema 23 and a couple of

others)

You need to buy elsewhere M6 studs long 300mm or more,

M16 nuts (be generous, you will use them a lot) M16 nylock nuts

(minimum 4) M16 wide washers (at least 8) interior diameter 16mm or

18mm “O” Rings (plumbing stuff) you will ned minimum 4 of them,

M4 nuts and bolts, M5 nuts and bolts.

2Bearings Outer Diameter

35mm, inner diameter 16mm, 11mm thickness (or near by)

each axis

takes two bearings they should be snug fit, zero play but not forced

in position, if you need to force them, better stop, take them out

and sandpaper work the hole around gently, and try again., once they

are in than take the 300mm threaded stud (may be even slightly

longer, but not shorter) and at one end fit a nylock nut until you

see a thread of the stud going out of the nylon lock, than tuck in a

washer, than one “O” Ring, than the pulley of your choice, than

another “O”Ring, than another washer than put the stud in from

the non flat side all way through to touch the bearing, at the other

end put in another washer, than a nylock nut, and while holding the

stud with a clamp somewhere thread that nut into the system until the

washer grips onto the bearings a bit, just enough to have zero play

without stopping the bearings from twisting, and test if the pulley

has a nice grip solid with the axis, if not, close a bit more the

nuts, like a quarter of a turn. Now is ready to fit cones and align

with other elements like the motor pulley, the level winder pulley

and the level winder filament path (trial and error till it works)

As transmission belts I am using some Kitchen elastics, wide

10 mm or more, thick at least 2 mm and at least 100 mm long when

measured flat (technically they are 200 mm around the circumference)

but have at hand also shorter and longer versions. They are cheap,

easy to replace and have a good grip.

You need Structural

Silicone (also known as sealant glue) to spread onto the cones

surface and their grip channel on the back, and let it dry a few days

before using it, that is to give a grip to the cones on the

spools.

Some pulleys you will note have some outer obstacles

around, you can use them as they are or cover the pulley with

structural silicone until the outer obstacles are covered by a mm or

two making your pulley a rubberised one, let it cure a few days

before using it.

level winder and spooler kit for filament 1.75 mm for 3 Kg spool

- Brand: 3D Mential

- Product Code: level winder and spooler for 1.75 mm for 3 Kg spool

- Availability: In Stock

-

£7.00

- Ex Tax: £7.00

Related Products

Filament accumulator kit

The production of 3D printer filament is hindered by a few major limitations, one being the requirement of uninterrupted filament extrusion without any changes in temperature, speed, or pulling tensioner. To address this, an accumulation buffer mechanism is needed to store the produced filament ..

£5.00 Ex Tax: £5.00

Tags: level winder, spooler kit, filament, 1.75 mm, 3 Kg spool, save the planet, climate change, plastic, reuse, recycle, recycling, repurpose, make your own filament, extrude filament, recuperate plastic, clean the environment.